GE Aerospace fully supports aviation industry efforts to decarbonize, which requires a holistic, global approach. Meeting the industry’s goal of net-zero CO2 emissions from flight by 2050 requires deploying revolutionary technologies to reduce emissions and to advocate for increased use and availability of alternative fuels, such as Sustainable Aviation Fuel (SAF) and hydrogen.

Air Transport Action Group declares net-zero CO2 goal

Members of Air Transport Action Group (ATAG), including GE Aerospace, adopted in October 2021 a long-term climate goal of net-zero carbon emissions by 2050, confirming the aviation industry’s commitment to reduce carbon emissions in support of the Paris Agreement 1.5ºC goal. This follows an earlier industry goal set in 2009.

Meeting the long-term net-zero goal requires the industry to deploy revolutionary technologies to reduce emissions and to advocate for increased use and availability of alternative fuels, such as Sustainable Aviation Fuel (SAF) and hydrogen.

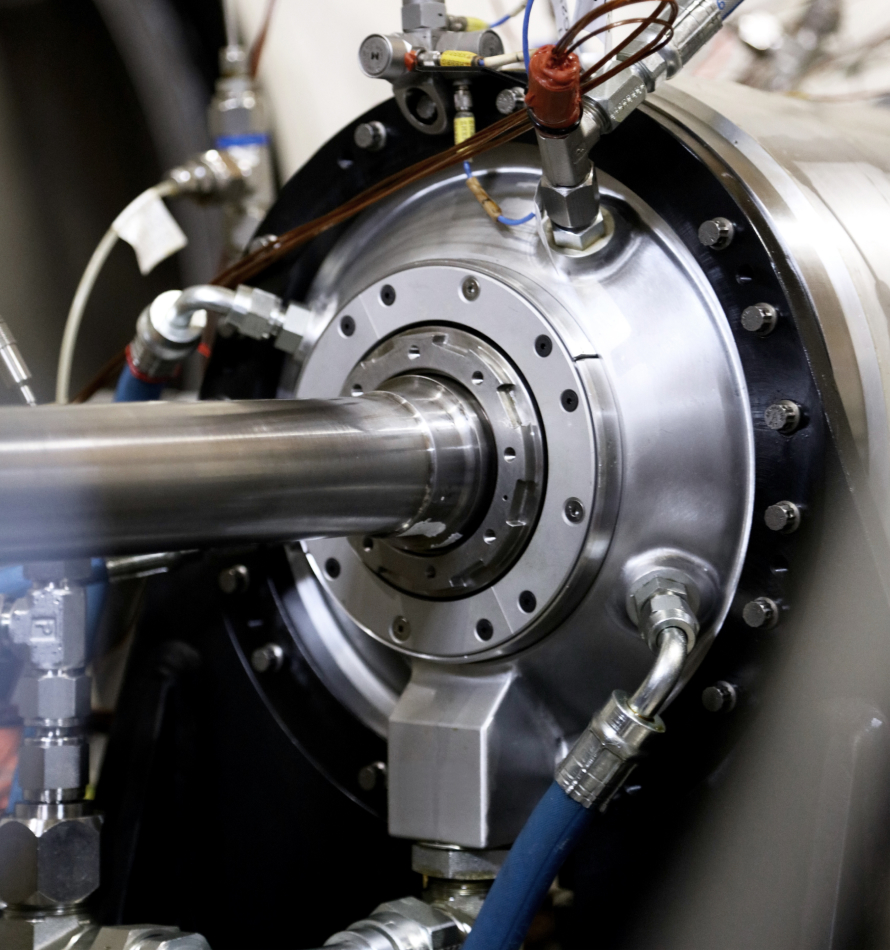

To address this challenge, GE Aerospace has embarked on multiple engine technology demonstrators to accelerate emissions-lowering technologies for aircraft propulsion. Two examples announced in 2021 include the CFM RISE* (Revolutionary Innovation for Sustainable Engines) Program in partnership with Safran Aircraft Engines and the Electrified Powertrain Flight Demonstration project with NASA. Additionally, GE has been actively involved in assessing and qualifying SAF since 2007 and works closely with SAF producers, regulators, and operators to ensure that SAF can be widely adopted for use in aviation.

United Flies World’s First Passenger Flight using 100% Sustainable Aviation Fuel

From the outside, there was nothing unusual about the Boeing 737 MAX 8 jet operated by United Airlines that flew from Chicago’s O’Hare to Washington’s Reagan National Airport with 115 people on board on December 1, 2021. But the plane made history. It was the first commercial flight with passengers on board to use 100% drop-in sustainable aviation fuel (SAF) for one of the aircraft’s two engines.

The jet used a pair of LEAP-1B engines developed by CFM International, a 50-50 joint company between GE and Safran Aircraft Engines. GE Aerospace has also been researching the use of SAF in its engines.