Propulsion

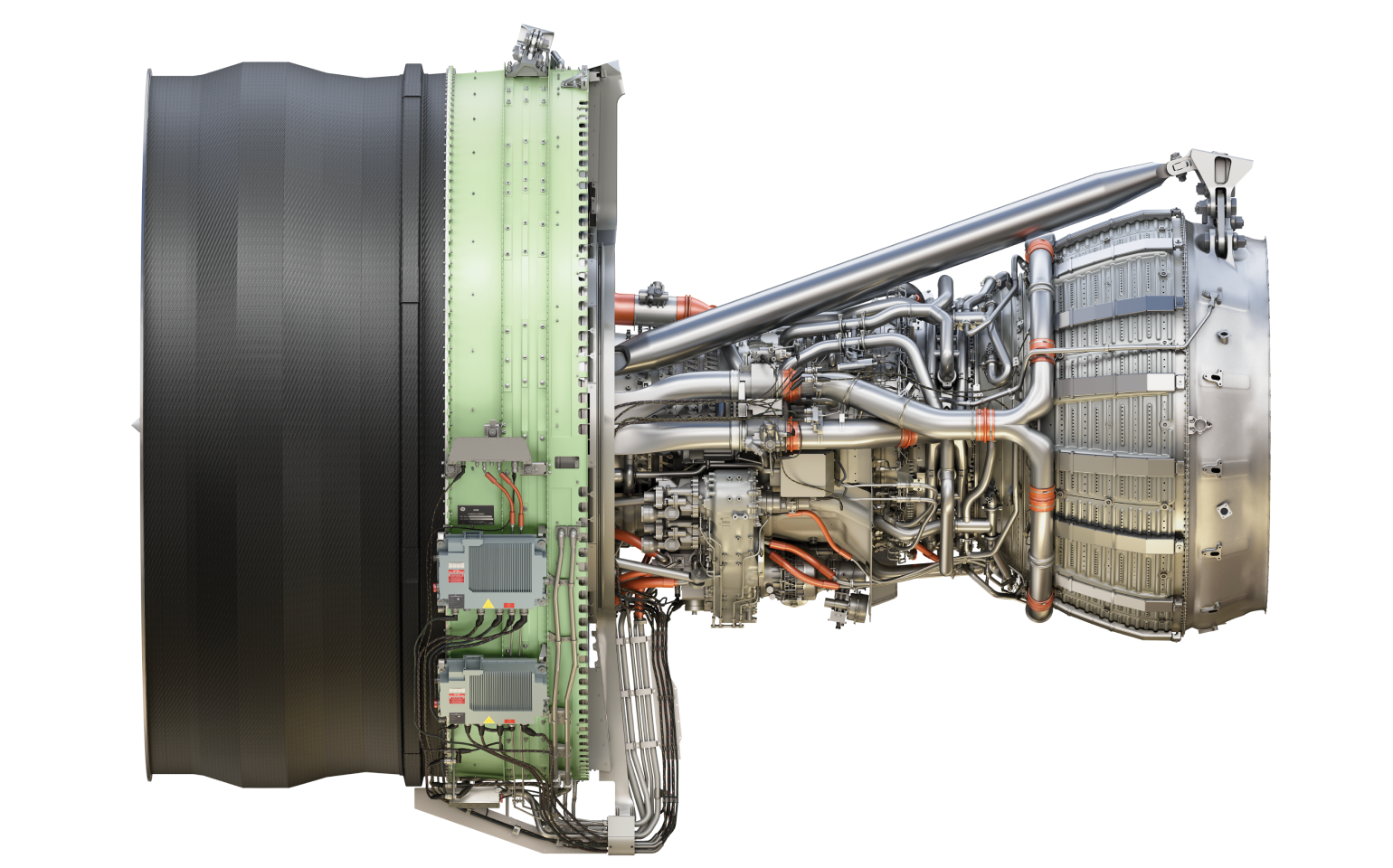

GE9X Engine

The GE9X is the largest and most powerful commercial aircraft engine ever built, incorporating advanced technologies that enable more efficient, quieter and with fewer emissions. Designed specifically for the new twin-engine Boeing 777X family, the GE9X is the most fuel-efficient engine in its class, designed to achieve 10 percent lower specific fuel consumption (SFC) compared to the GE90-115B

The most advanced technologies and materials

Innovation is in our DNA. Like every engine that we have ever built, new technologies and materials incorporated into the design are key to delivering the world-class reliability, efficiency, and performance GE engines are renowned for

This blend of evolutionary and revolutionary designs enables the GE9X to be the most fuel-efficient jet engine GE has ever produced on a per-pounds-of-thrust basis. The GE9X powering the 777X airplane family:

The GE9X features the same world-class reliability as the GE90-115B, with noise and NOx emissions well below anticipated regulation standards. Environmental performance highlights include:

All emission values equal or exceed current regulatory requirements and are expected to remain well below the requirement for many years to come.

The GE9X engine produces half the NOx of any engine in its class at a level that is less than half of current requirements.

" It takes the world’s best talent in jet propulsion to create a game-changing product like the GE9X engine. There is no substitute that can achieve the combination of size, power and fuel efficiency of the GE9X. This engine will deliver unsurpassed value and reliability to our airline customers."

John Slattery, Executive Vice President and Chief Commercial Officer, GE Aerospace

FAA Certification awarded September 25, 2020