Propulsion

The T901 Turboshaft Engine

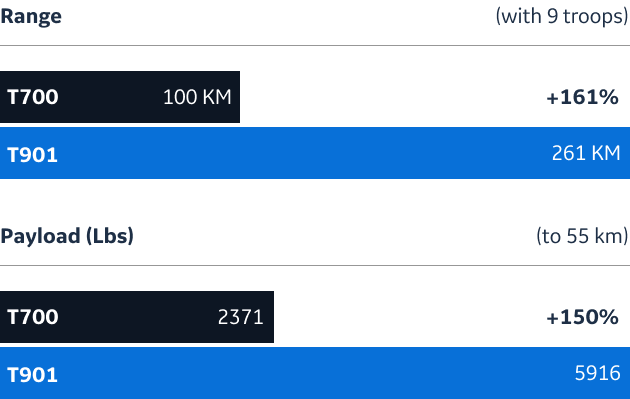

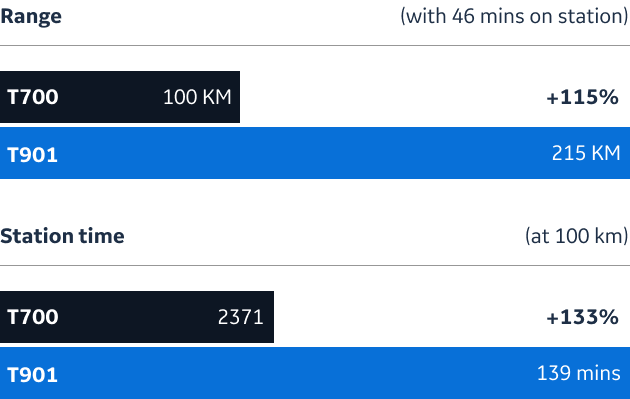

As Apache and Black Hawk helicopters add capabilities and associated weight, they are also required to perform at higher and hotter conditions than originally designed. This led to the need for increased power over the previous T700 engine. In response, GE developed the T901 by building on GE’s unparalleled experience and record with the U.S. Army’s Apache and Black Hawk helicopters. The T901 engine provides 50% more power 25% better specific fuel consumption, and reduced life cycle costs -with fewer parts, a simpler design, and proven, reliable technology.

More power

Better specific fuel consumption

AH-64 and UH-60 Experience

Reliable Fix-Forward Design

6,000 feet / 95 degrees F

6,000 feet / 95 degrees F

Developed with the most advanced and proven 21st century aviation innovations, GE’s T901 engine benefits from GE’s investment in both military and commercial technologies, allowing war fighters to focus on what’s important—mission accomplished.

The T901 engines use of CMCs enables the engine to produce more power with less weight. Higher temperature capability means more engine airflow can go towards powering the helicopter.

The T901 is designed using GE's industry-leading 3D aerodynamics design tools validated in the Advanced Affordable Turbine Engine (AATE), Future Affordable Turbine Engine (FATE), and Improved Turbine Engine Program (ITEP) prototype engine programs. This design practice leads to:

These improvements contribute to the T901 exceeding T700 climb requirements by 6000 feet anddelivers performance to meet the 95 degree F heat requirements.

The T901 directly benefits from GE's industry-leading additive manufacturing capabilities. This technology enables game changing system solutions which result in improved performance with significantly fewer parts, maximizing reliability while reducing weight and cost.

GE's next generation of engine cooling capabilities maximize T901 performance. These technologies allow the engineto reduce the amount of cooling air required to maintain the same engine temperature, delivering more power and significantly improved fuel efficiency. The results:

GE's next generation of engine cooling capabilities maximize T901 performance. These technologies allow the engineto reduce the amount of cooling air required to maintain the same engine temperature, delivering more power and significantly improved fuel efficiency. The results:

The Army's Apache and Black Hawk helicopters operate in the world's harshest conditions. For nearly 40 years GE engines have supported keeping them in the fight. Five million hours of desert operations experience has influenced the T901 Inlet Particle Separator (IPS), allowing the U.S. Army to fly with confidence in the harshest conditions. The new IPS reduces sand ingestion and pressure loss, decreases wear on turbomachinery components, and provides significant time-on-wing improvement. The T901 includes multiple sand-tolerant design features, including: