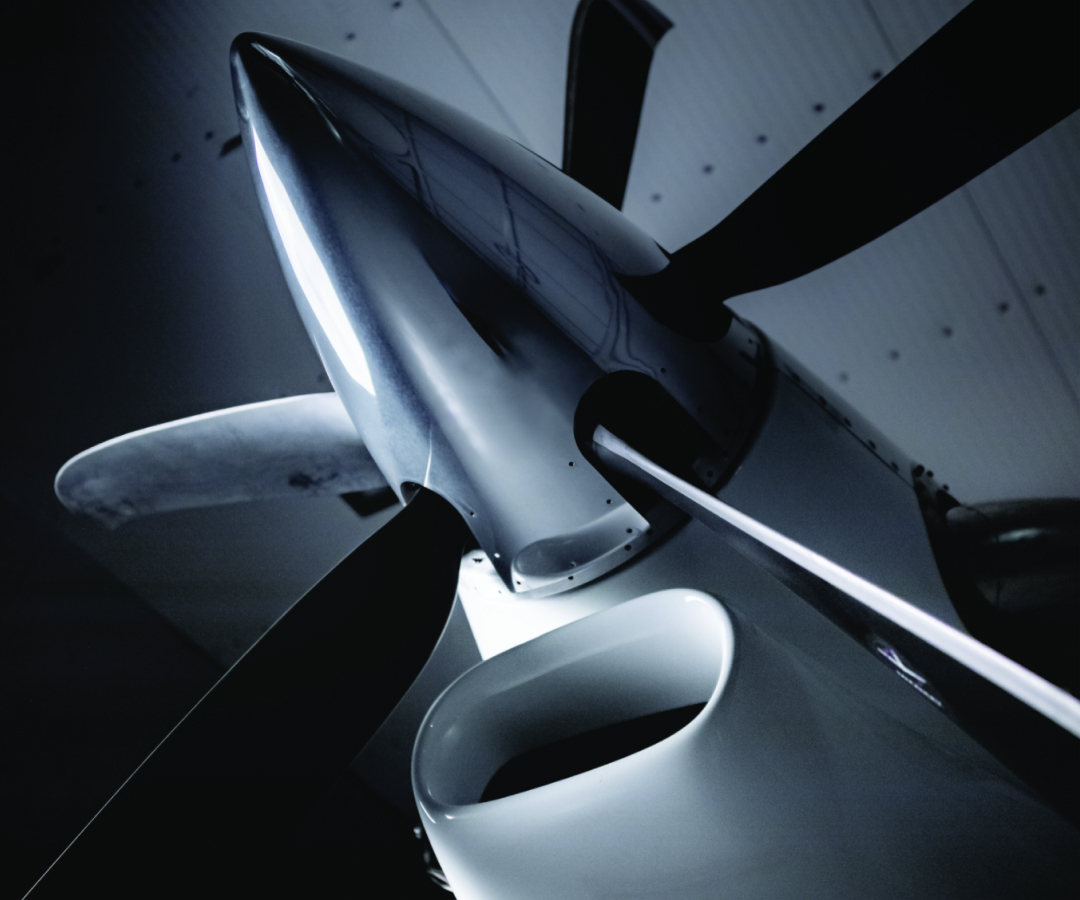

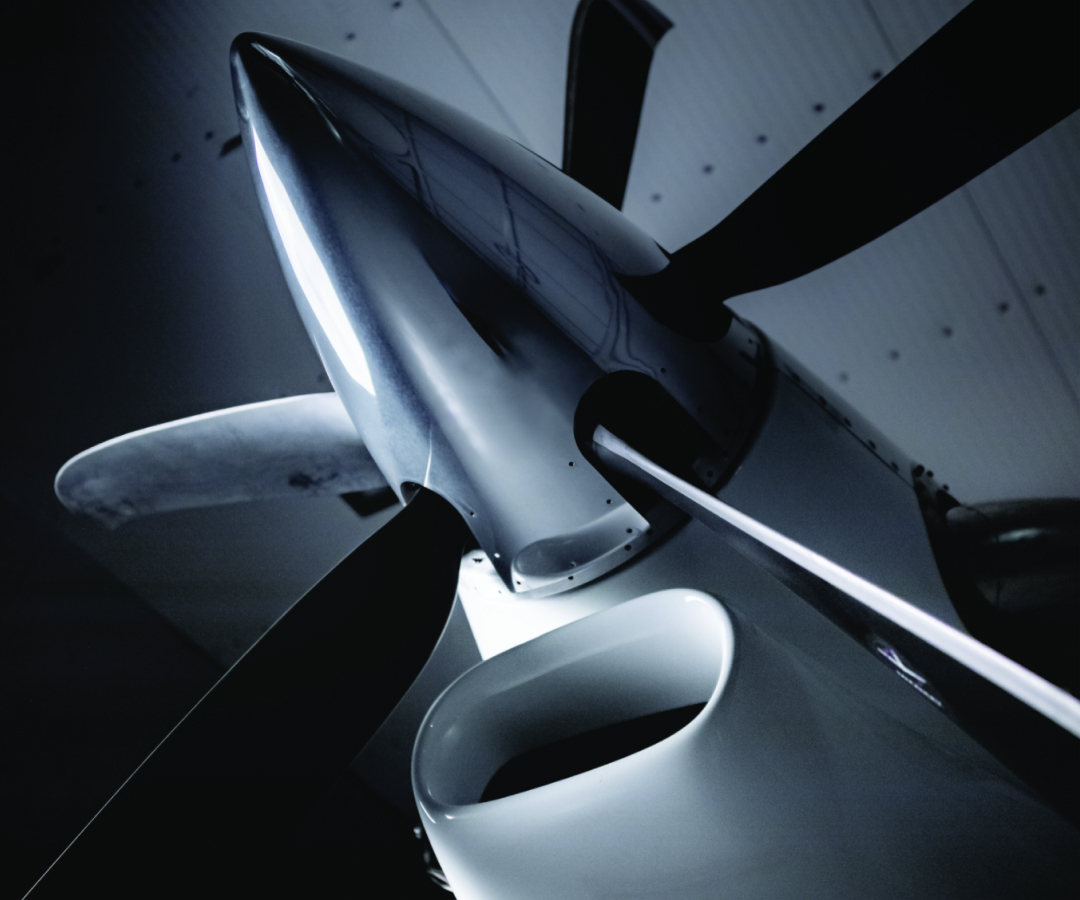

Propulsion

The Catalyst Engine

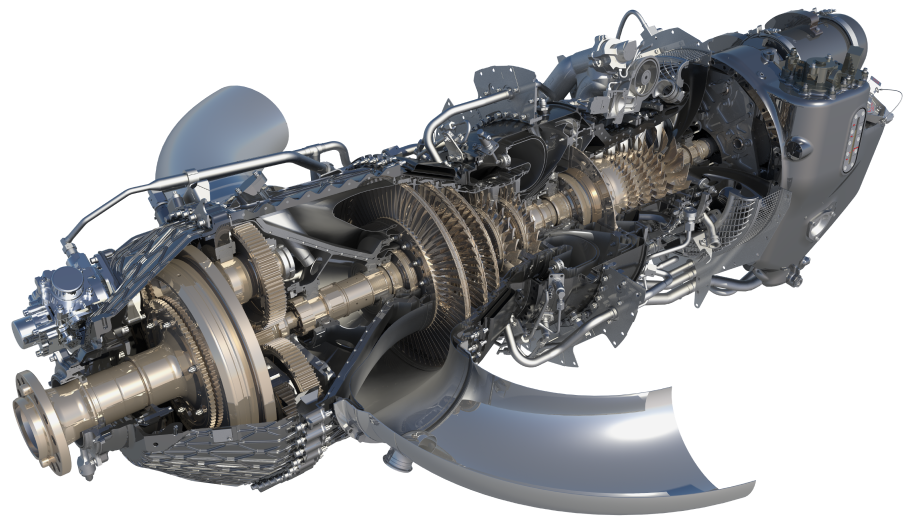

The Catalyst™ engine features an industry-best 16:1 overall pressure ratio enabling the engine to achieve as much as 20 percent lower fuel burn and 10 percent higher cruise power compared to competitors in the same size class.

The propeller gearbox uses planetary gears to supply power generated by the power turbine to the propeller at a significantly reduced RPM. The engine will feature multiple versions of the gearbox to handle a variety of RPM and Shaft Horsepower (SHP) combinations from 850 to 1,650 SHP.

The three-stage power turbine connects to the propeller gearbox and provides power for the aircraft propeller. Use of three stages combined with 3D aerodynamic design maximizes the power extraction and efficiency across the entire flight envelope.

The two-stage high pressure turbine (HPT) drives the engine compressor. The HPT blades feature 3D aerodynamic design, single crystal technology and internal air cooling passages to allow for high temperature operation, maximizing efficiency and power extraction.

The compact, reverse-flow combustor and advanced fuel nozzles enables efficient combustion. Utilizing advanced combustor capabilities, the GE Catalyst engine will feature major reductions in emissions and soot over current engines in this class.

The compact four-stage axial single centrifugal compressor is designed with GE fourth generation 3D aerodynamic design capabilities. A class-leading 16 to 1 pressure ratio provides high efficiency and power in a very compact design.

Variable geometry compressor stator vanes ensure maximum performance and robust operations over the entire flight envelope.

The all-new integrated propulsion control (IPC) features a single lever integrated electronic engine and propeller control. This integrated approach coordinates and optimizes engine and propeller operation across the entire flight envelope.

The accessory gearbox is driven by the engine core and provides the mechanical power for engine accessories. Reduction gears within the gearbox transfer the power to multiple pads on the gearbox at reduced RPM.

The Catalyst engine - aimed at the 850-1600 SHP range - is the first modern turboprop ever built with 3D-printed parts, writing a pioneering chapter for the aviation industry. Avio Aero and GE’s engineers incorporated customer feedback into the engine’s design and development, for engineering design flexibility and a more pleasant, quiet, and sustainable journey for pilots and passengers.