Propulsion

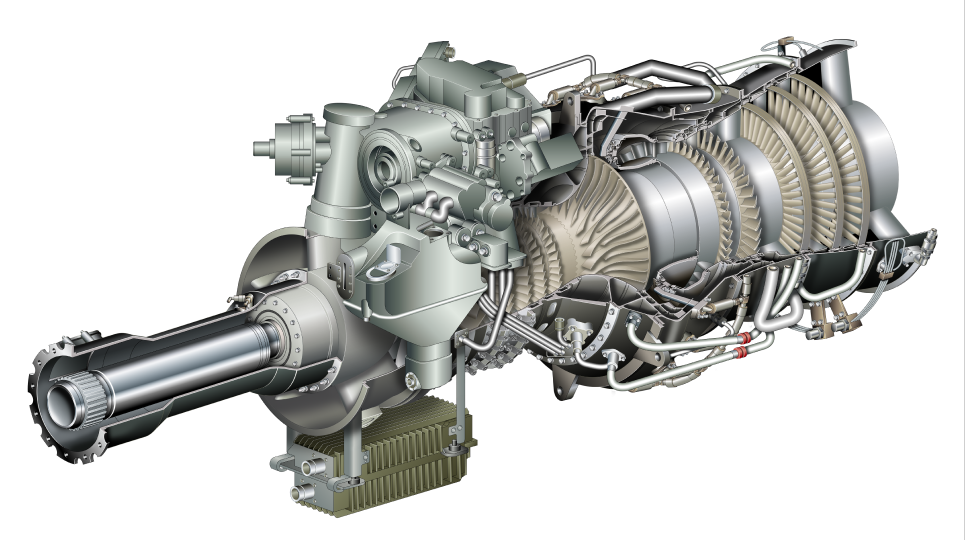

GE’s T408 Turboshaft Engine

When compared to its predecessor – GE's T64 turboshaft engine powering the CH-53E Super Stallion aircraft – the T408 provides transformational performance improvements. To date, the T408 has logged more than 11,000 hours of ground and flight test in support of a variety of Department of Defense (DoD) programs.

More Power

Better specific fuel consumption

Fewer Parts

Reliable Fix-Forward Design

The T408 combines breakthrough technologies, innovative cooling schemes, and modern-day durability to deliver numerous mission-critical advantages in the world’s harshest operating environments.

GE’s T408 is equipped with Full Authority Digital Engine Control (FADEC) with prognostics and health management to improve performance and reduce maintenance cost.

Engine-mounted FADEC with prognostics and health management to improve performance and reduce maintenance cost

Modular engine with sealed oil sumps and accessible gearbox for ease of field maintenance

Rugged compressor with split casing and erosion coating to increase time-on-wing

Robust, efficient combustor designed for reliability

Modern turbine aerodynamics, materials and cooling schemes for durability and efficiency

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.