Services

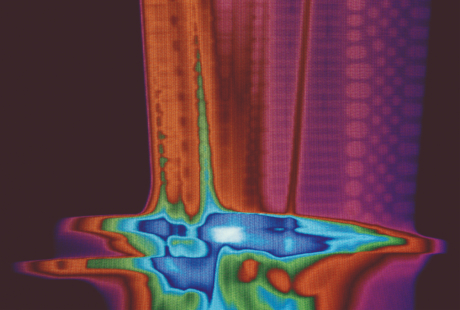

TrueChoice Material

With TrueChoice™ Material, high quality OEM new and used parts, advanced repairs, and technology upgrades for airlines and MROs are in our DNA. It’s all part of our commitment to offering more material options to enhance engine performance and reduce your cost of operations.

When GE delivers an engine into service, we are in it for the long haul. That’s why we offer a wide variety of TrueChoice Material offerings – including new parts, used parts, repair, and upgrades – that address MROs’ needs as well as operators’ maintenance, ownership horizon, asset value, and overall fleet management requirements.

Our customer portal – myGEAviation.com – is available for online ordering, of an order, or for technical support. In addition, we offer 24/7 customer service through GE Aerospace Fleet Support.

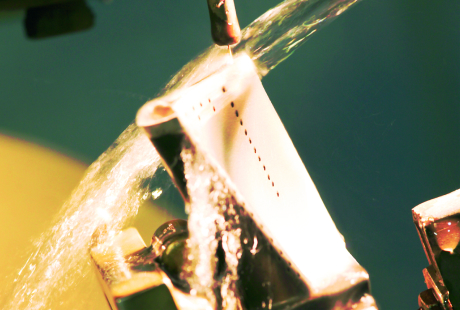

Repairs are guaranteed for workmanship for 4,000 engine flight hours (up from the original 2,000) or 2,000 part cycles or 24 months following redelivery, whichever occurs first for CFM56-3/5A/5B/7B/5C engines.

For CF6-80C/80E engines, the coverage has been tripled to 6,000 engine flight hours or 1,500 part cycles or 24 months following redelivery, whichever occurs first. For CF34-8/10 engines, the coverage is 3,000 engine flight hours or 2,300 part cycles or 18 months following redelivery, whichever occurs first.